Less than a year after the U.S. Navy touted how purchasing missile tube assemblies in advance for its future Columbia-class ballistic missile submarines had helped trim the cost of the program, the service says it has uncovered faulty welds in those components that will need potentially costly and time-consuming fixes. The tubes are common to the Block V Virginia-class attack submarines and the U.K.’s Dreadnought-class ballistic missile boats, as well, and the issue could lead to delays in building all three types.

Defense News was the first to report the problems on Aug. 6, 2018. Naval Sea Systems Command’s (NAVSEA) is now investigating all the work that BWXT, Inc., a sub-contractor to General Dynamics Electric Boat, has done on the common missile tubes so far. The firm has delivered seven of the assemblies already and is in the process of building five more.

“All BWXT welding requiring volumetric inspection has been halted until the investigation is complete,” Bill Couch, a spokesperson for NAVSEA, told Defense News. “Initial reports indicate that the other vendors do not have the same issue, and they continue to produce missile and payload tubes.”

The Navy has not said how many of BWXT’s tubes have known issues. An unnamed source told Defense News that the firm itself discovered the substandard welds, but it is unclear how and when it got reported to both General Dynamics Electric Boat and the U.S. government.

The service expects to purchase a total of 12 Columbia-class boats, which will eventually take the place of the Cold War-era Ohio-class. General Dynamics Electric Boat and Huntington Ingalls Industries’ Newport News Shipbuilding will be involved in the production and the lead ship is supposed to enter service in 2031 if everything goes according to plan.

In addition, the U.S. Columbia-class and the U.K. Dreadnought-class will carry their Trident D-5 nuclear-armed

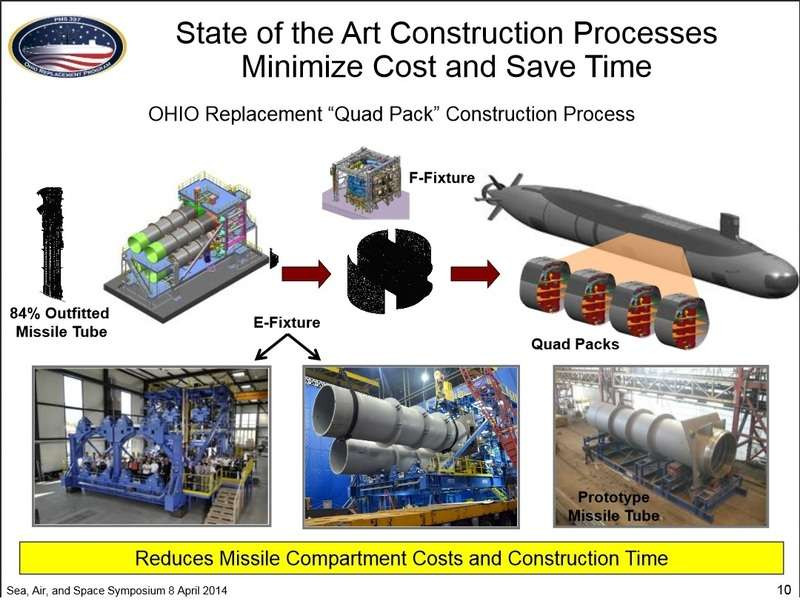

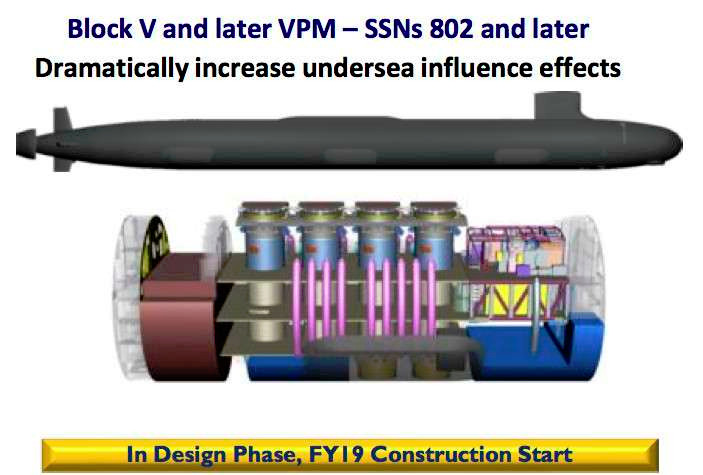

submarine-launched ballistic missiles in multiple “quad pack” Common Missile Compartments, a deliberate decision to simplify the process of building the two types of subs and hopefully save money. The Block V Virginia-class doesn’t use the complete assembly, but the four tubes in its new Virginia Payload Module, or VPM, are of a common design, again to trim costs and streamline production.

With regards to the Columbias, General Dynamics Electric Boat and Huntington Ingalls Industries’ Newport News Shipbuilding will slot the compartments into the submarines at the appropriate time during construction. In the past, the shipyards had only purchased these components near to when the rest of the boat was ready, leading to small, irregular, and costly orders and added time to the overall production schedule.

The Navy has long touted this concept as essential to keeping the price of the new ballistic missile boats as low as possible and keeping their delivery on schedule. So a problem with the tubes presents a significant issue.

“We’ve already reduced cost by $80 million per hull, to bring [average procurement unit down to $7.21 [billion],” U.S. Navy Rear Admiral Michael Jabaley, the Program Executive Officer for Submarines at NAVSEA, said at the Naval Submarine League’s annual conference in November 2017. “So that was a combination of missile tube continuous production … and advance construction, which is pulling key construction activities to the left. Really the focus of that was to reduce the risk of not delivering on time, but it had an added benefit of savings as well.”

The concern is that BWXT’s welds could be a sign of other problems from the Navy’s push to ramp up production of the Columbias and new submarines in general, especially given the firm’s excellent existing quality record, according to Defense News. At present, the General Dynamics Electric Boat and Huntington Ingalls Industries’ Newport News Shipbuilding are on a schedule where they each deliver one Virginia-class boat a year.

The Navy hopes to add delivery of one of its new ballistic missile submarines each year on top of that and still have Virginias only take around 60 months to build in total. Needless to say, this is an ambitious goal.

“Both shipbuilders hired additional people to account for the increase to two submarines per year,” Rear Admiral Jabaley had told Defense News in March 2017. “As a result, obviously when you bring in an influx of new people your level of experience goes down.”

It’s still too soon to tell whether BWXT’s troubles stemmed from this need to significantly increase production of the missile tubes, other factors, or a combination of both. If the former issue turns out to be the primary reason, it could call into question whether the shipyards can meet the Navy’s demands.

And depending on how widespread the issue is, it could have cascading impacts on the delivery timetable for the Navy’s Columbias and Block V Virginias, as well as the Dreadnoughts for the Royal Navy. The Virginia-class is already on a very tight schedule to meet the two-boats-a-year requirement.

Delays and cost increases could be even more problematic for the Royal Navy, which is reportedly staring down a possible funding gap of more than $7.7 billion for the Dreadnought-class over the next decade. Budget shortfalls combined with the United Kingdom’s planned exit from the European Union have already led to deep budget cuts and the country’s naval forces have already been hit particularly hard.

“Impacts to the delivery of missile tubes to the U.K. will be assessed upon completion of GDEB’s [General Dynamics Electric Boat] efforts to define and scope next steps,” Couch, the NAVSEA spokesperson, told Defense News. “The Navy is assessing the potential impact to Virginia-class submarines with VPM.”

Couch added that the Navy had been buying the tubes ahead of time specifically to help mitigate risk and that delivery of the future USS Columbia remained on schedule. But until its investigation into the situation is complete, the Navy might not really know just how widespread and serious the deficient welding is for the tubes or the submarines production timetable as a whole.

The service has also not said how much it expects the repairs to cost. In September 2017, General Dynamics Electric Boat received a $5.1 billion contract just to finish design work ahead of the planned start of Columbia’s construction in 2021. A report from the Congressional Research Service

in July 2018 pegged the full cost of the 12-boat program at more than $122 billion already.

All of this comes at a time when the Navy is struggling to maintain its existing submarine fleets, which could give it a very little margin for delays in getting its new boats into service. As of October 2017, 15 Los Angeles– and Virginia-class types had been sitting idle for a total of 177 months collectively due to a backlog in regular maintenance availabilities both at the service’s own shipyards and those that contractors operate.

“If you have a submarine that’s tied up in the shipyard, then obviously they’re not operating,” U.S. Navy Vice Admiral Joseph Tofalo, the Navy’s top submarine officer, told Breaking Defense at the Naval Submarine League conference in November 2017. “It’s probably most manifest in our ability to surge in time of crisis. We meet our … demand on a day to day basis, but the impact would be, if there’s a crisis, then your surge tank is low.”

Significant delays in the delivery of new submarines would only exacerbate this deficiency. This, in turn, could put the Navy in an even more worrying predicament as small hostile states, such as North Korea, along with potential near-peer opponents, primarily Russia and China, look to step up their own submarine and other underwater activity.

Hopefully, the Navy will be able to quickly isolate this new issue with the Common Missile Compartments and exploit the long-lead purchasing it has already done to otherwise mitigate any issues in the near- or long-term.

Contact the author: jtrevithickpr@gmail.com