As the U.S. Air Force pushes to be more prepared to operate on short notice from remote or austere locations with limited support, one simple question may increasingly be on the minds of its F-16 Viper pilots: how will I get in and out of my jet? One of the service’s officers currently stationed in Italy is pitching a solution to that problem.

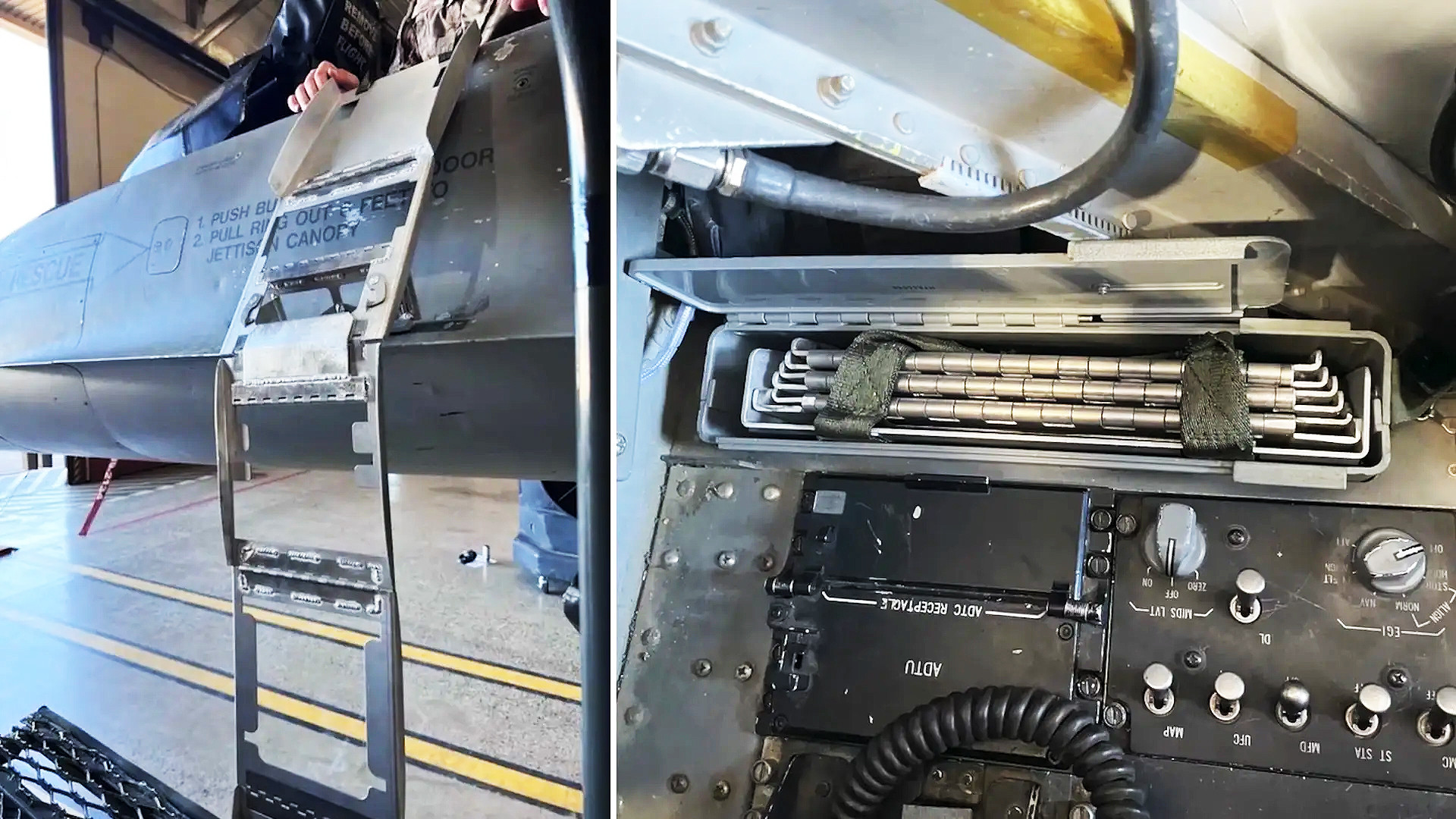

For the F-16, which does not have a built-in boarding ladder, a folding one that can fit right in the jet’s map case in the cockpit seems like a revelation. Fielding it would also be significantly cheaper than the external ladders now in use, each one of which costs $5,200.

Air Force Maj. Nicholas “Trapper” Atkins, an F-16 pilot with the 31st Fighter Wing, submitted the idea for the internally stowable F-16 boarding ladder on behalf of a team as part of a “Spark Tank” competition at Aviano Air Base in Italy. For years now, the service has been encouraging units around the world to hold these kinds of innovation competitions to solicit ideas directly from officers and enlisted airmen that can help improve operational effectiveness and reduce costs.

A prototype example of the folding ladder has already been built by members of the 31st Fighter Wing, which has been working with Air Combat Command Training Support Squadron, Detachment 9 at Luke Air Force Base in Arizona on the project. The Delaware Resource Group (DRG) of Oklahoma, a Native American-owned defense contractor in that state, looks to have been involved, as well.

The design, seen in pictures at the top of this story and in at rending above, weighs just six pounds and cost $1,800 to make ($300 in parts and $1,500 in labor), according to an Air Force video, seen below, detailing the pitch.

Exactly how heavy the existing external boarding ladders that the Air Force uses with its F-16s are is unclear, but the narrator in the Spark Tank video says each one costs the service $5,200.

In addition, “it costs about $6,800 to move a pallet of them on a C-130” cargo aircraft, the narrator adds. “Attempts have been made at getting private sector involvement, but it has been cost prohibitive at $86,000 for the prototype, and $26,000 per ladder.” No further details about those industry proposals are provided.

A picture of a different collapsible ladder for use with the F-16, designed to fit inside a standard baggage pod rather than in the cockpit, has been circulating online since at least 2018. However, that ladder’s construction, consisting of a central tubular metal frame with foot holds welded on at various points, all attached to a plate at the top that latches onto the rim of the cockpit when the canopy is raised, also looks likely to have been locally fabricated. Last year, personnel with the Air Force’s 35th Fabrication Flight, part of the 35th Fighter Wing at Misawa Air Base in Japan, showed off a very similar tubular ladder they had crafted that was also intended to be carried inside a baggage pod.

Why this all matters is that, as we noted earlier, the F-16 lacks a built-in boarding ladder. This is not the case on many of the other tactical combat jets the Air Force currently operates, including its stealthy F-35A Joint Strike Fighters. Air Force F-15s and A-10s also have integrated boarding ladders.

This means that ladders “must be pre-positioned ahead of time to [allow pilots to] safely get into and out of the cockpit,” the narrator of the Spark Tank video explains. “Unfortunately, … legacy ladders are far from ideal, being heavy, expensive, [and] bulky.”

The pitch video adds that the need to send the ladders to forward locations would take “up valuable space in an ACE movement.”

ACE here refers to Agile Combat Employment (ACE), a set of concepts of operations that the Air Force has been developing and refining in recent years. ACE is centered on the ability of aircraft to rapidly deploy with minimal support to a growing number of forward locations, many of which are remote and/or austere, and do so in more unpredictable ways.

So, finding new and improved ways for combat aircraft to bring ground support equipment and other materiel, and even additional munitions to help with sustained operations, along with them to these sites is of great interest. With all this in mind, the map case ladder design also has advantages over the baggage pod type that has been previously seen, which takes up space in those underwing stores that could be used to carry other items. Having to carry a baggage pod at all limits what an F-16 can bring with it to a forward location. It also results in a performance hit, causing increased fuel burn and reduced range.

The ACE concept is being driven in large part by increasing concerns about the vulnerability of large established facilities to enemy stand-off strikes, especially in the context of a potential high-end conflict against a near-peer adversary like China. The development of new fixed-position and deployable base defenses, as well as additional ways to deceive opponents and conceal friendly forces, are also components of ACE.

F-16s still make up the plurality of the Air Force’s combined tactical combat jet fleets and many of them are in the process of receiving substantial upgrades. For the foreseeable future, Vipers are expected to be part of “the leading edge of the Air Force’s Agile Combat Employment initiative,” according to the Aviano Spark Tank video.

A stowable boarding ladder for the F-16 could also be valuable outside of ACE operations. Should a Viper need to divert to an expected location for any reason, having a ladder inside the cockpit would allow the pilot to more readily get in and out without having to wait for some kind of solution to be devised on the ground. With many established bases expected to come under heavy attack in the opening phases of any future major conflict, unexpected diversions are also a major factor when it comes to ACE.

Any suitably tall ladder could probably do in a pinch in any of these contexts, but would not necessarily be ideal. At the same time, there are also questions about how sturdy a six-pound sheet metal ladder that can fold up to fit in a map case might be, especially for routine use during sustained operations. More robust external ladders could, of course, be brought to forward locations later on.

There is certainly interest across the Air Force in this kind of capability, and not just for the F-16. Earlier this year, a collapsible boarding ladder that fits in the cockpit of an F-22 Raptor stealth fighter, another type without this feature built in, was tested as part of a larger Air National Guard-led ACE-focused exercise nicknamed Hoodoo Sea. The War Zone has reached out for more information about that ladder design.

Maj. Atkins, who is leading the F-16 ladder project at Aviano, is clearly very confident in his team’s particular design.

“What we need from the Air Force is, one, subject matter experts. … we need immediate subject matter expert support to cut through the red tape for authorization and certification,” Atkins says in the Spark Tank pitch video. “Then, two, we help financially to help rollout for ladder, not just for the 51 F-16s at the 31st Fighter Wing, but for the 936 F-16s in the Air Force inventory.”

“We anticipate 18 ladders per squadron,” he adds, proposing a plan that would see the first batch of ladders go to Air Force units in Europe and then send additional ones to forces in the Pacific region.

Whether or not this pitch is picked as part of the Spark Tank competition at Aviano or otherwise pursued by the Air Force, and how the ladders might work out when subjected to real routine use, remains to be seen.

Whatever the case, the various stowable ladder projects for the F-16, as well as the F-22, underscore that there are real questions about how to ensure that pilots will be able to get in and out of certain jets at forward locations during future distributed and expeditionary operations.

Contact the author: joe@thedrive.com