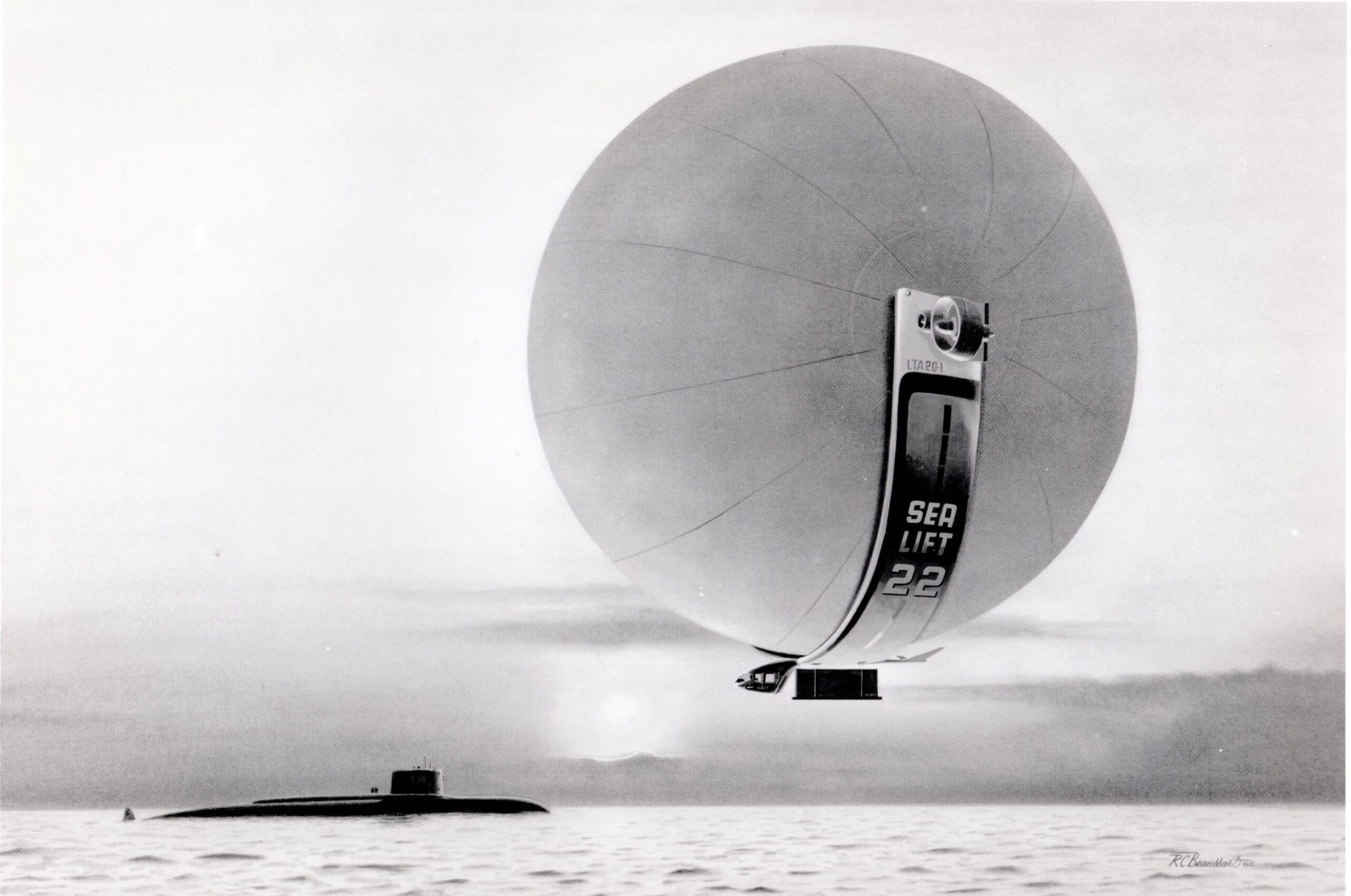

Magnus Aerospace Corporation’s LTA 20-1 had all the hallmarks of 1980s space-age futurism. Its design looked very much out of this world and would have been right at home as an alien spacecraft in an episode of Star Trek: The Next Generation. The aerostat featured a highly unique means of propulsion wherein its spherical balloon, once filled with helium, would rotate, lifting it into the air and sending it on its way by what’s known as the ‘Magnus Effect.’

While the project is now long defunct, which is par for the course for exotic lighter-than-air endeavors of the last 40 years, its history is quite fascinating, and speaks to the current growing interest in lighter-than-air craft.

LTA 20-1’s story began in the early 1980s, during which time the Canadian inventor and entrepreneur Frederick D. Ferguson took an interest in airship development and research. Ferguson happens to be the great-great-grandson of the inventor Samuel F. B. Morse. Most notably, Morse contributed to the invention of a single-wire telegraph system in the mid-nineteenth century and co-developed Morse code.

Ferguson originally began developing LTA 20-1 under the Van Dusen Development Corporation, which was formed in October 1980, as its director. Less than a year later, he established a new corporation, Magnus Aerospace Corporation, in September 1981, also serving as its director. Although Van Dusen appears to have officially amalgamated into the Magnus Aerospace Corporation in 1988, their titles were used interchangeably in connection with the LTA 20-1 project throughout the early to mid 1980s.

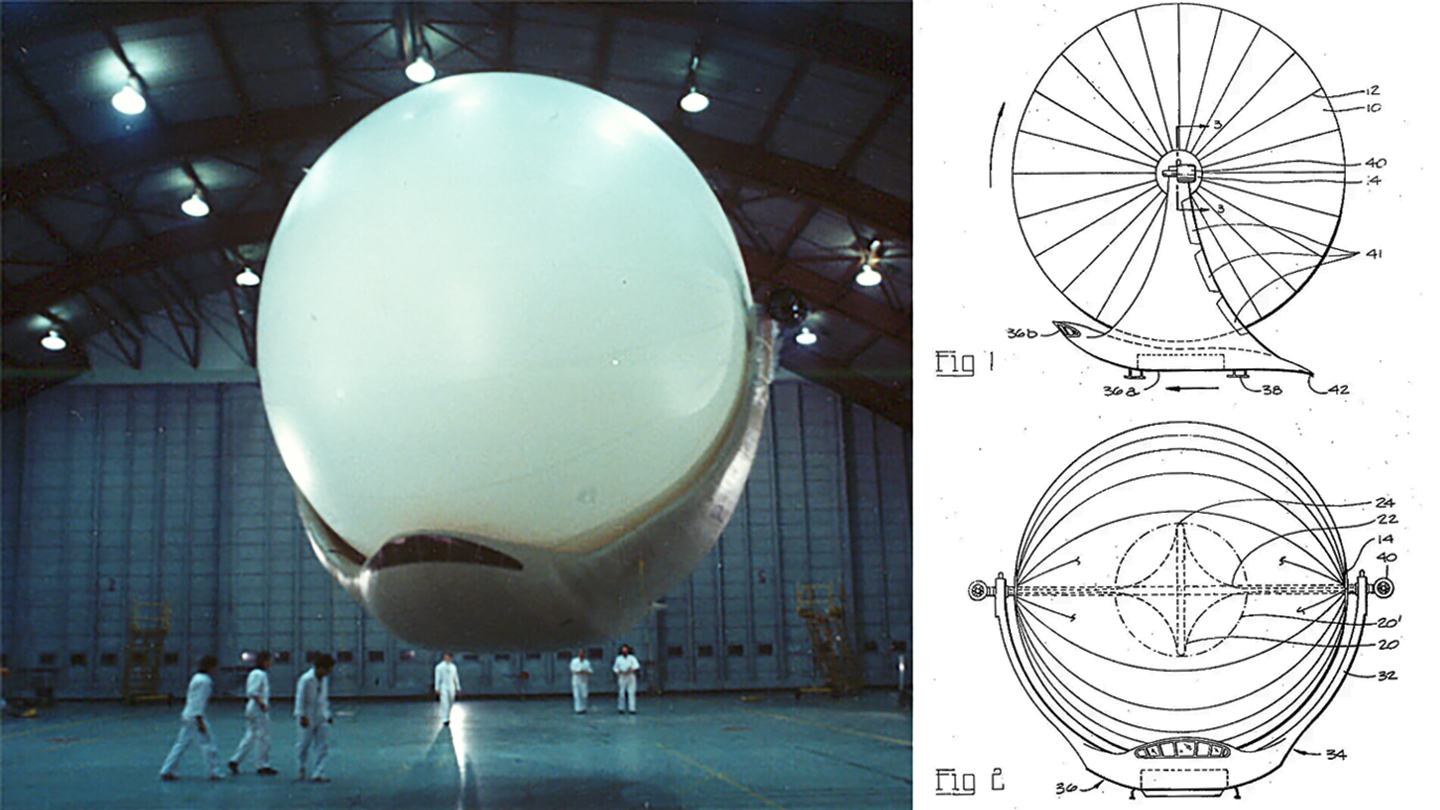

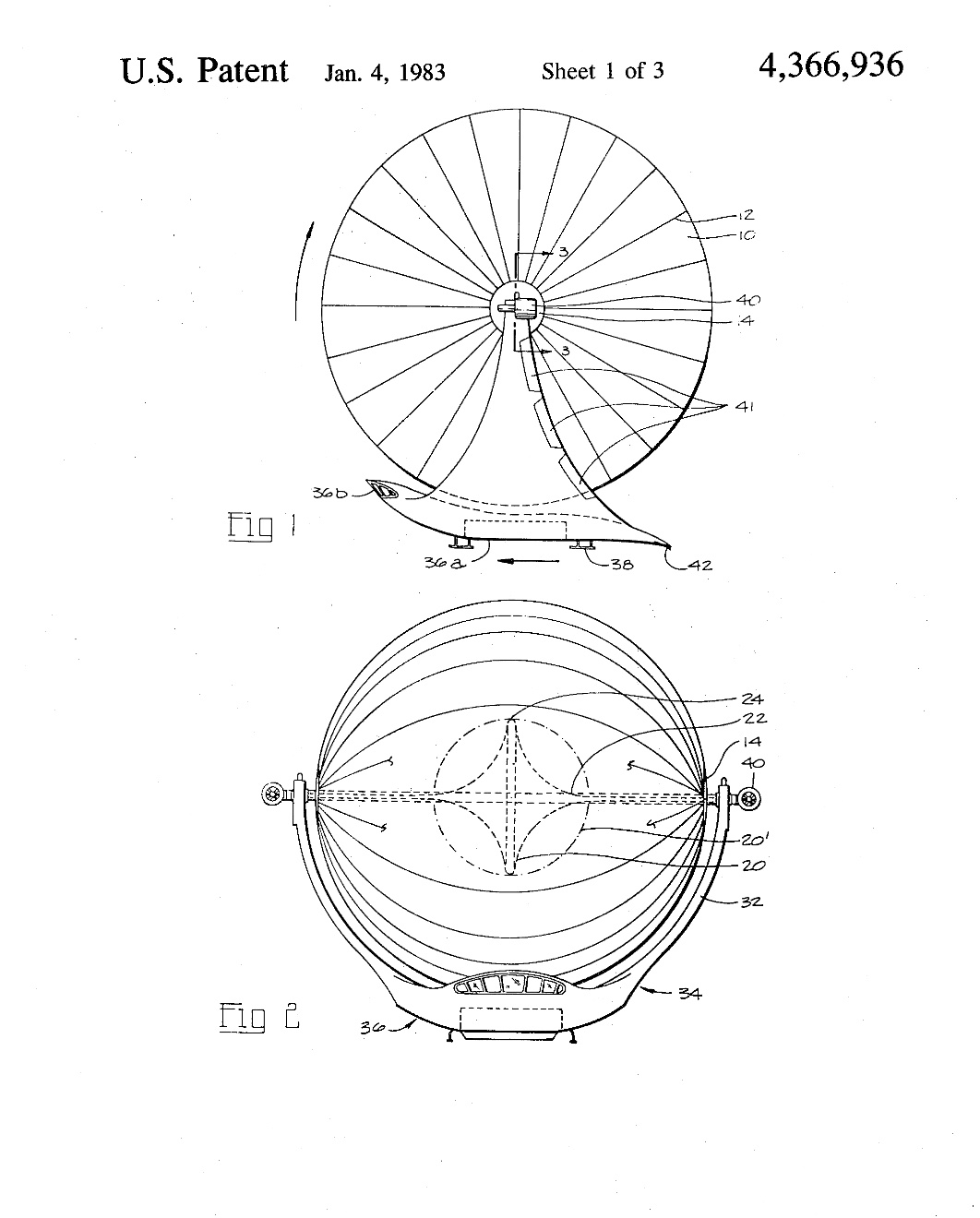

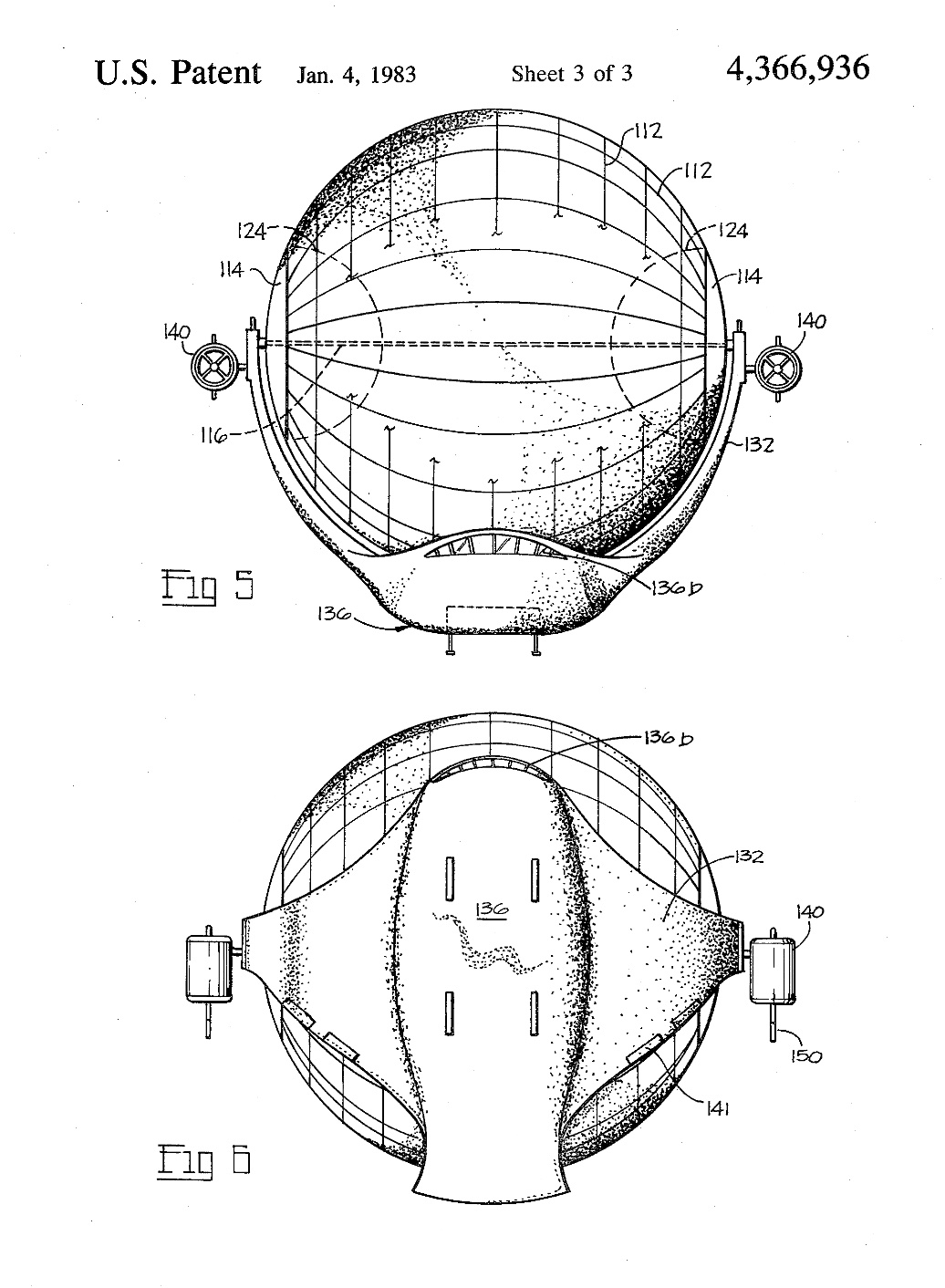

As part of the initial phase of getting the project up and running, Ferguson filed a patent for the aerostat in late 1981 titled “aircraft having buoyant gas balloon,” which was subsequently granted in early 1983. That contraption, the patent’s abstract says, would feature a large spherical balloon, with fixed dimensions when inflated, filled with a lighter-than-air gas, such as helium.

Using a buoyant gas like helium “at a pressure sufficiently high that the shape and size of the balloon… [would be] substantially unaffected by normal changes in atmospheric pressure and temperature” would allow the airship to be moored, and have cargo attached to it, in adverse weather conditions, according to the patent documentation.

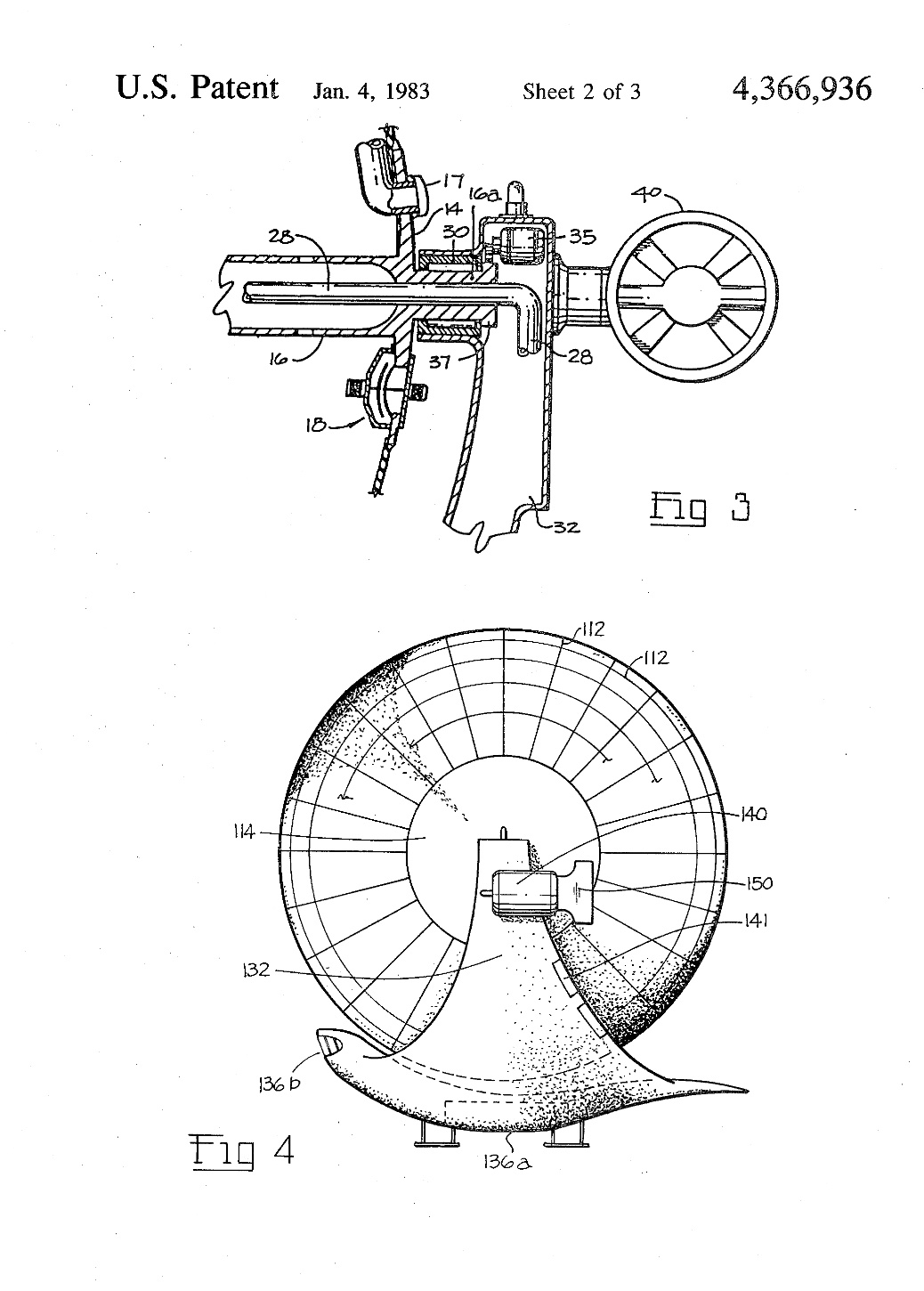

The spherical balloon, the patent explains, would be “rotatably mounted on a normally horizontal axle having end portions projecting from opposite sides of the balloon.” A ballonet, inside the main sphere and attached to the axle, would be used to alter the vehicle’s buoyancy by providing in-flight trim control and air ballasting.

Moreover, the alien-looking and highly streamlined “rigid load supporting yoke,” comprising two arms extending upwardly from a “central load engaging means” (such as a gondola) would suspend from the axle. The arms, seen in the diagram below, would carry gas turbine engines driving variable pitch propellers in ducted pods that could rotate. The engines were designed to assist with vertical takeoff and provide forward propulsion/steering in the air. At the forward end of the gondola, a front-facing cabin was located for crew members. The cabin would be pressurized to allow the vehicle to operate at altitudes of up to 15,000 feet.

In order to take off, the vehicle combined three sources of lift: aerostatic lift from gas inside the balloon, dynamic lift from vectored thrust engines, and lift from the aforementioned Magnus Effect, which relates to the generation of force from a spinning cylindrical or spherical objects.

The latter phenomenon was first described by the German physicist and chemist H. G. Magnus in 1852, during investigations into why cannon balls curve as they fly through the air.

The Magnus Effect is often explained in relation to how soccer players can kick balls around a wall of defenders or when tennis players apply topspin to their groundstrokes. When in motion, a spinning object exerts a net force on the air which, according to Newton’s third law of motion, exerts an equal and opposite force back on the moving object. This alters the object’s trajectory, as air gets dragged along with the direction of motion.

As part of his patent, Ferguson included design specifications for two separate airships, one with a smaller spherical balloon measuring 72 feet in diameter (designated 72P) and a larger one with a balloon measuring 160 feet in diameter (designated 160P). Both variants would be capable of the same airspeed of 70 miles per hour, although the expected maximum Magnus lift in pounds differed greatly between the two — 30,000 pounds in the case of the larger balloon, and 6,000 pounds in the case of the smaller. As Ferguson further stipulated, however, figures on Magnus lift for the two variants were “approximate pending large scale experiments.”

At around the same time as Ferguson filed the patent for the design, a scaled test version of LTA 20-1 was rolled out by the Magnus Aerospace Corporation. Citing details provided by Ferguson, an article from the November 30, 1981, edition of Aviation Week & Space Technology reported that validation testing with the prototype showed the concept performed as predicted.

The LTA 20-1 test version measured 20 feet in length and 23 feet in height, costing $2.5 million at the time, the article states. Whether this was U.S. or Canadian dollars remains unclear; $2.5 million in 1981 U.S. dollars would be equal to nearly $8.8 million today. While its balloon was made from a polyurethane-coated nylon fabric, the Aviation Week article notes that the full-scale design would likely utilize Kevlar. Moreover, it also indicated that compared to the prototype’s use of “two ducted turbofans,” the full-scale version would feature Rolls Royce Tyne R Ty. 20 Mk. 801 turboprop engines.

Following prototype validation tests — the specifics of which remain unclear — Magnus Aerospace Corporation established an ongoing research project in 1982 to develop the vehicle’s aerodynamics and structural design. Ferguson contracted with various Canadian universities to begin testing other sub-scale models of LTA 20-1. The University of Toronto’s Institute for Aerospace Studies (UTIAS) subsonic aerodynamics group tested more than 100 model configurations of LTA 20-1 in their wind tunnel from 1983. They also built and tested a number of small free-flying test articles.

Ferguson also contracted with a team at Carleton University in Ottawa to build and test-fly a 19-foot diameter model version of the airship, which went on to feature in many of the company’s promotional photos of the aerostat. A scale model of the Magnus craft was also demonstrated at the U. S. Naval Academy on November 20, 1984, although which version specifically remains unclear.

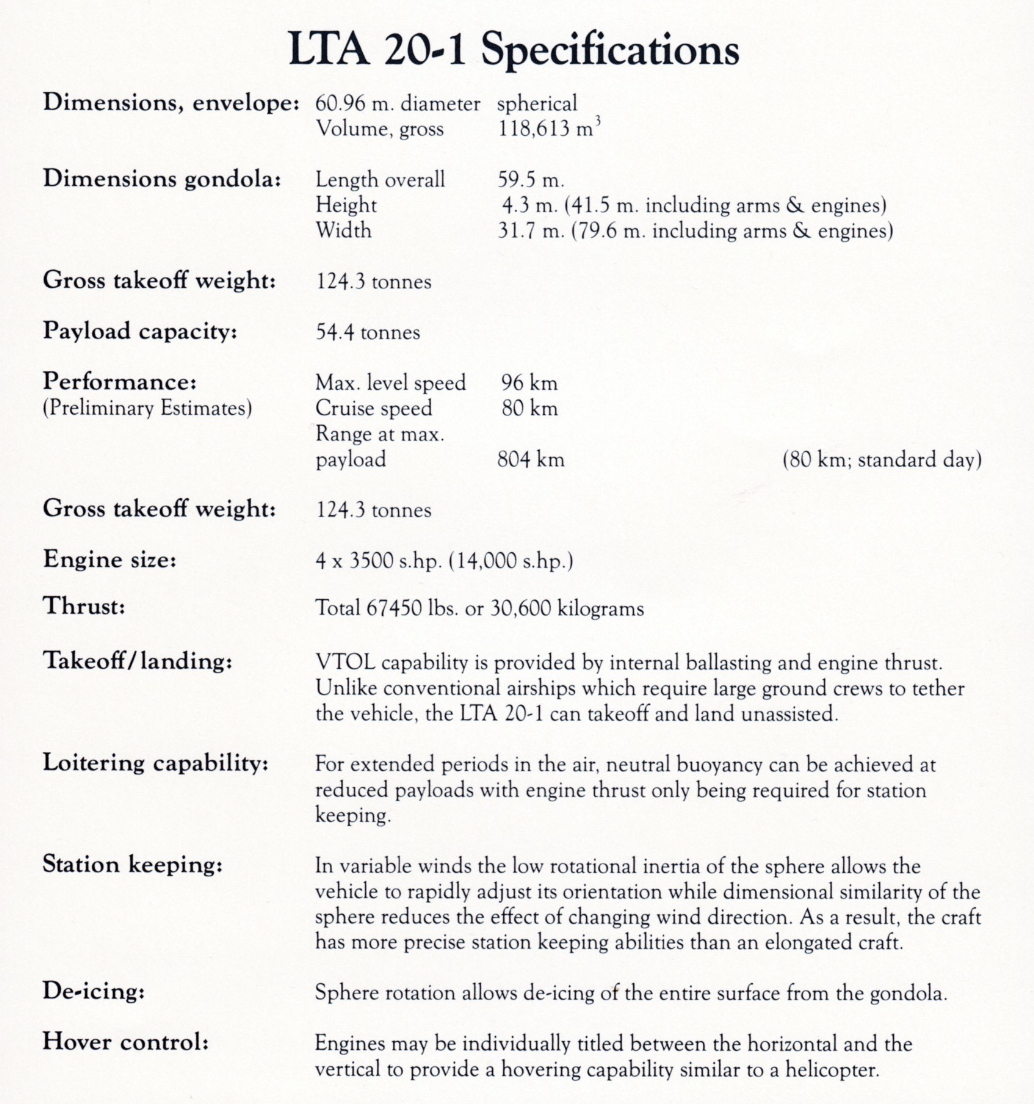

As the finalized specifications for LTA 20-1 highlight, arrived at after its structural design was established, the full-size aerostat would feature an even larger evelope than 160P detailed in Ferguson’s earlier patent. Compared to the 160 foot diameter envelope of 160P, the final full-size version would feature a balloon with a 60.96 meter (200 foot) envelope. Other specifications on LTA 20-1’s performance, including its payload capacity of 54.4 tonnes (some 109,00 pounds), as well as a fully loaded range of 804 km (500 miles) and a cruise speed of 80 km (50 mph), can be seen in the image below taken from a Magnus Aerospace Corporation brochure.

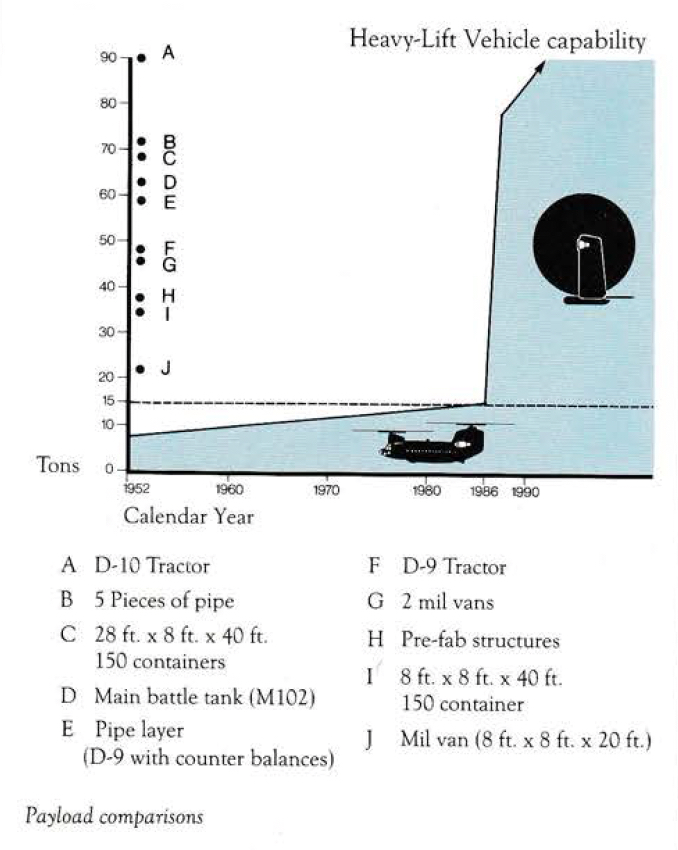

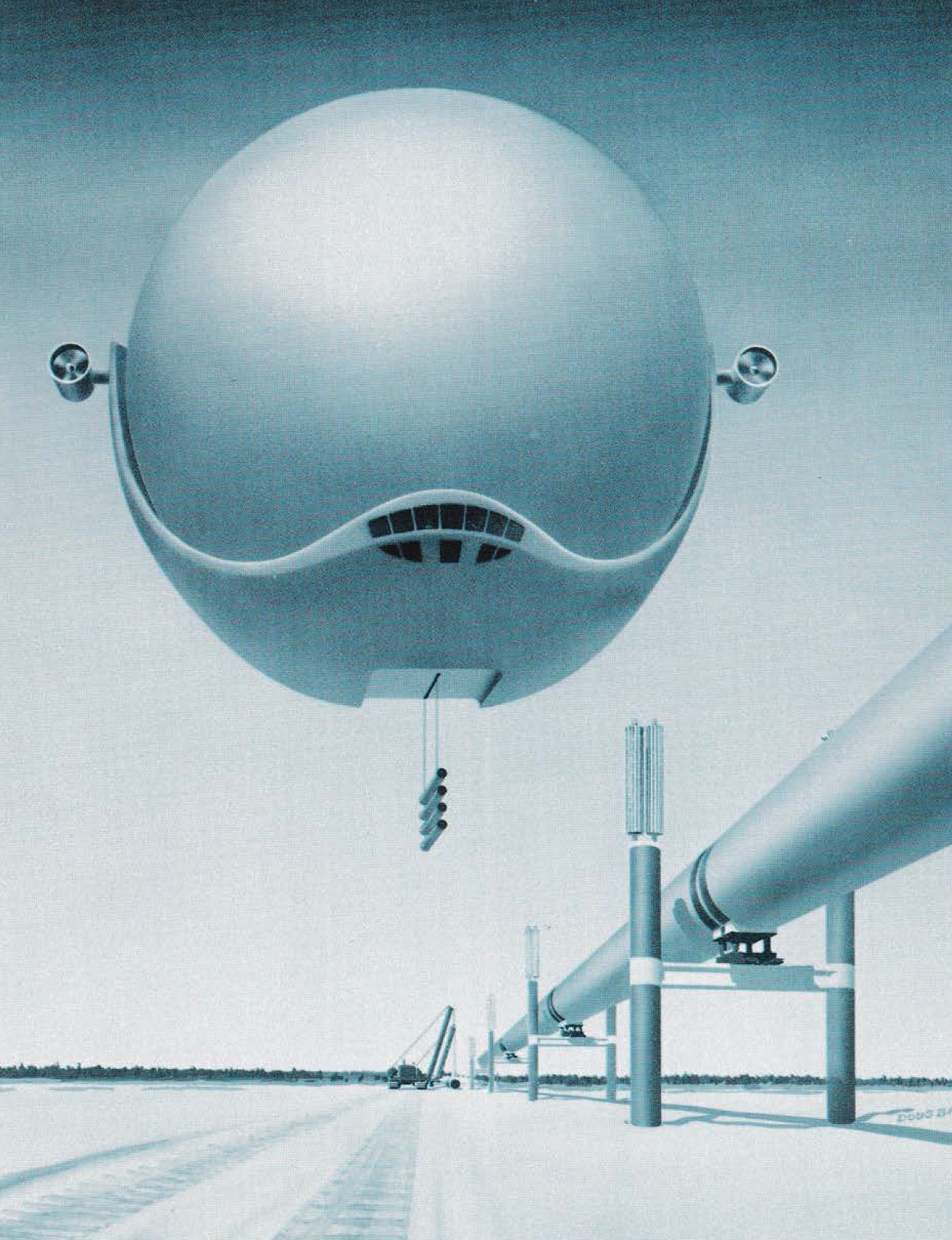

As to what LTA 20-1 was intended to be used for, a different promotional brochure from 1984 described it as being specifically designed to operate in a similar manner as a helicopter, but with the ability to carry far greater payloads. Magnus Aerospace Corporation also stressed that LTA 20-1 would be able to provide “economic transport to inaccessible locations,” operating at “greatly reduced costs per unit of flight.”

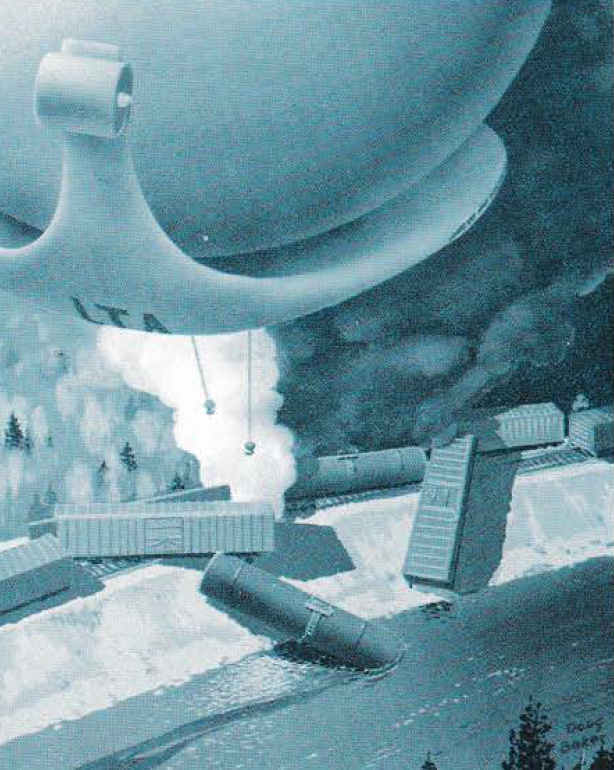

In terms of commercial capabilities, LTA 20-1’s combination of heavy-lift and vertical takeoff and landing capabilities would make it useful in a variety of contexts, the brochure notes, including; the transportation of heavy construction equipment (such as pipeline construction), emergency response (carrying relief supplies or moving heavy objects), and resource development in remote areas (oil, gas and mining industries).

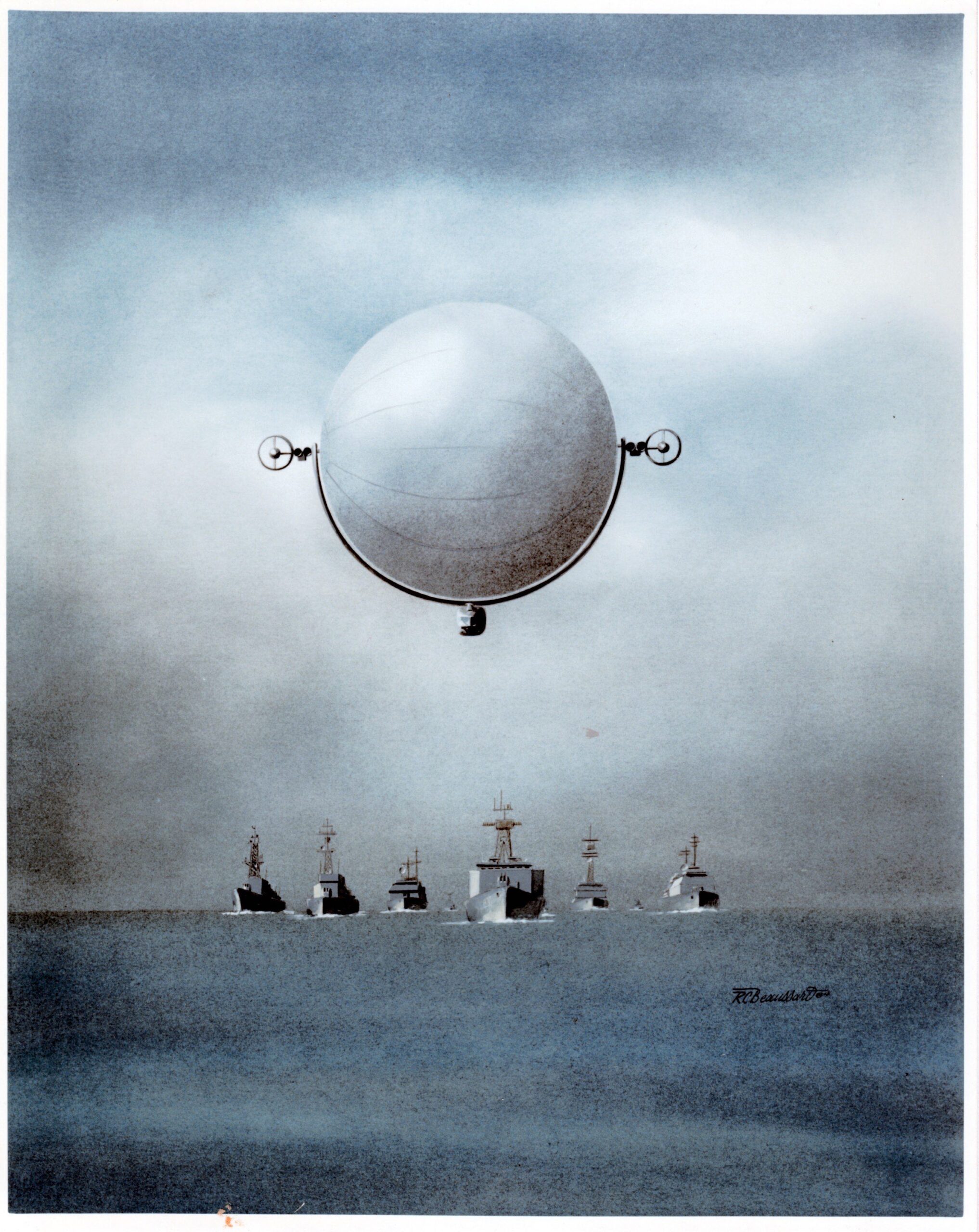

Magnus Aerospace Corporation also stressed that the craft could be used in military contexts for the transportation of heavy equipment and supplies, although few specific details beyond heavy lifting were provided.

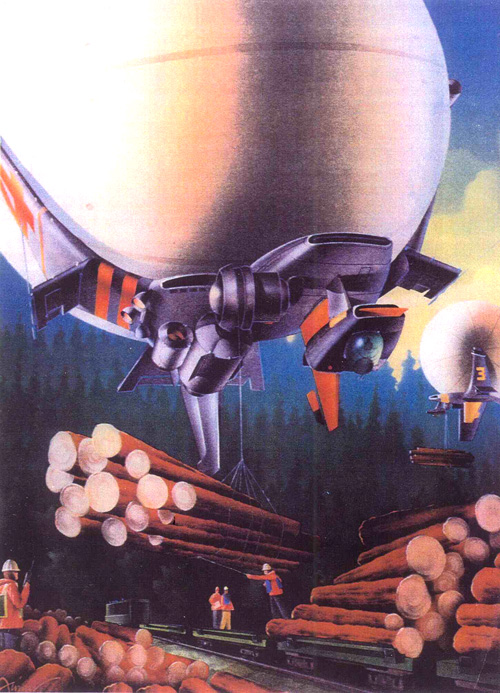

One particular industry the corporation aimed to target was logging. A specific “logging version” of the aerostat, which featured a balloon 28 meters (some 92 feet) in diameter would supposedly be able to carry a payload of 16,000 kilograms (some 35,000 pounds) at zero fuel. The vehicle could be used for roughly 2.5 hours during a typical yarding operation, so the corporation claimed.

“In the logging industry, steep terrain, prohibitive road development costs and a short operating season virtually eliminate the feasibility and profitability of harvesting rich forest areas,” the brochure reads. “With the LTA 20-1 [logging version], the entire operation’s flexibility is considerably increased. With heavy-lift aerial logging, fewer roads are required. By targeting their operations towards a particular variety or grade of timber in demand, companies can react quickly to changing market conditions.” Futuristic artwork of LTA 20-1s carrying lumber was also produced by the corporation to underscore this.

In 1986, Magnus Aerospace Corporation aimed to issue stock in Canada in order to scale up the project, as well as affiliate with an aerospace manufacturer. Despite interest from some foreign companies, notably C. Itoh & Co. and Nissho Iwai based in Japan, which were interested in representing Magnus Aerospace Corporation in the Pacific Rim, it never built a full-scale version of the LTA 20-1. The corporation was later dissolved entirely in 2002.

Yet the end of the corporation did not stop Ferguson from experimenting with designs centered on the Magnus Effect. In this clip from 2010, for example, a Magnus Effect prototype airship, designed specifically for generating electricity by Ferguson, can be seen. More recently he has turned his attention to innovating in other areas of clean energy creation. Within the past few years, the Canadian-based Waterotor Energy Technologies, Inc. — of which Ferguson is CEO — designed and developed a vertical twin-rotor water turbine apparatus for generating energy from ocean currents, rivers, and canals. It’s the company’s hope that the design can be used to harness clean energy from slow-moving water currents globally in the years to come.

While LTA 20-1 never made it to full-scale testing, let alone production, in recent years there’s been a revival of interest in lighter-than-air vehicles, especially for military applications. The U.S. and Chinese armed forces, in particular, have explored various high-altitude lighter-than-air projects, often intended as surveillance platforms designed to travel across long distances and for long durations. The Chinese spy balloon — which was shot down by a U.S. Air Force F-22 on February 4 off the coast of South Carolina — underscores this, which featured a large payload apparatus for intelligence gathering. Interest in lighter-than-air craft for communications relay, drone motherships, and even kinetic strikes has increased in recent years, as well.

Regardless of the outcome, LTA 20-1 certainly represented an ambitious project with a wide range of possible applications. And, on top of that, it featured some extraordinary engineering via its use of the Magnus Effect and an out-of-this-world design to go with it.

Contact the author: oliver@thewarzone.com