The U.S. Navy’s Infrared Search And Track System, or IRST, intended for its F/A-18E/F Super Hornet fighter jets, is still to join the fleet, more than four years after it entered production. The podded IRST, seen as a critical tool to retain the Navy’s air-to-air advantage over potential adversaries, was first flown on a Super Hornet in late 2019, but operational testing is not now expected to begin until early next year.

The U.S. Government Accountability Office (GAO), in its latest Report to Congressional Committees, provides an update on the status of the IRST pod, which is still dogged by production quality issues and which officials worry could be subject to more delays in the future. All this is happening at a time when an IRST capability is arguably more important than ever.

In the past, we have looked extensively at the advantages an IRST pod will bring to the Super Hornet community and the Navy’s tactical aviation branch as a whole.

To summarize, an IRST sensor is entirely passive, using the infrared spectrum alone to detect and track airborne targets, including those at far beyond visual range. With no radio-frequency emissions, the target won’t be alerted to the fact that they’ve been detected and are being tracked.

As stealth technology and advanced electronic warfare capabilities continue to proliferate, the arguments behind introducing an IRST become even more compelling. By their nature, IRST sensors are immune to electromagnetic jamming and other electronic attacks and can literally see through radar-evading stealth technology.

As well as operating as a standalone sensor, an IRST can furthermore make use of sensor-fusion capabilities, adding a critical sensor data stream to enhance a flight crew’s situational air-to-air ‘picture’ in conjunction with more traditional sensors.

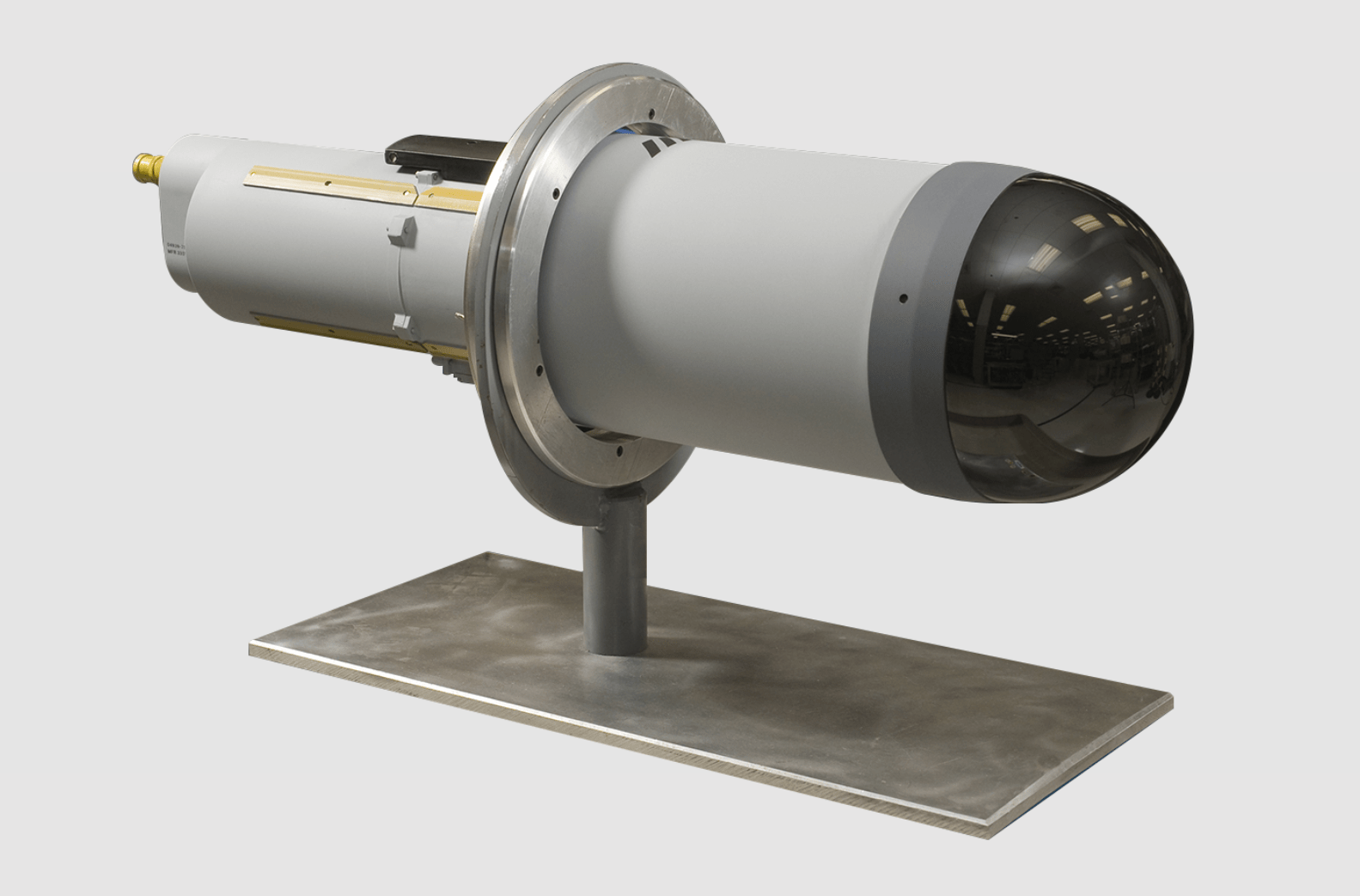

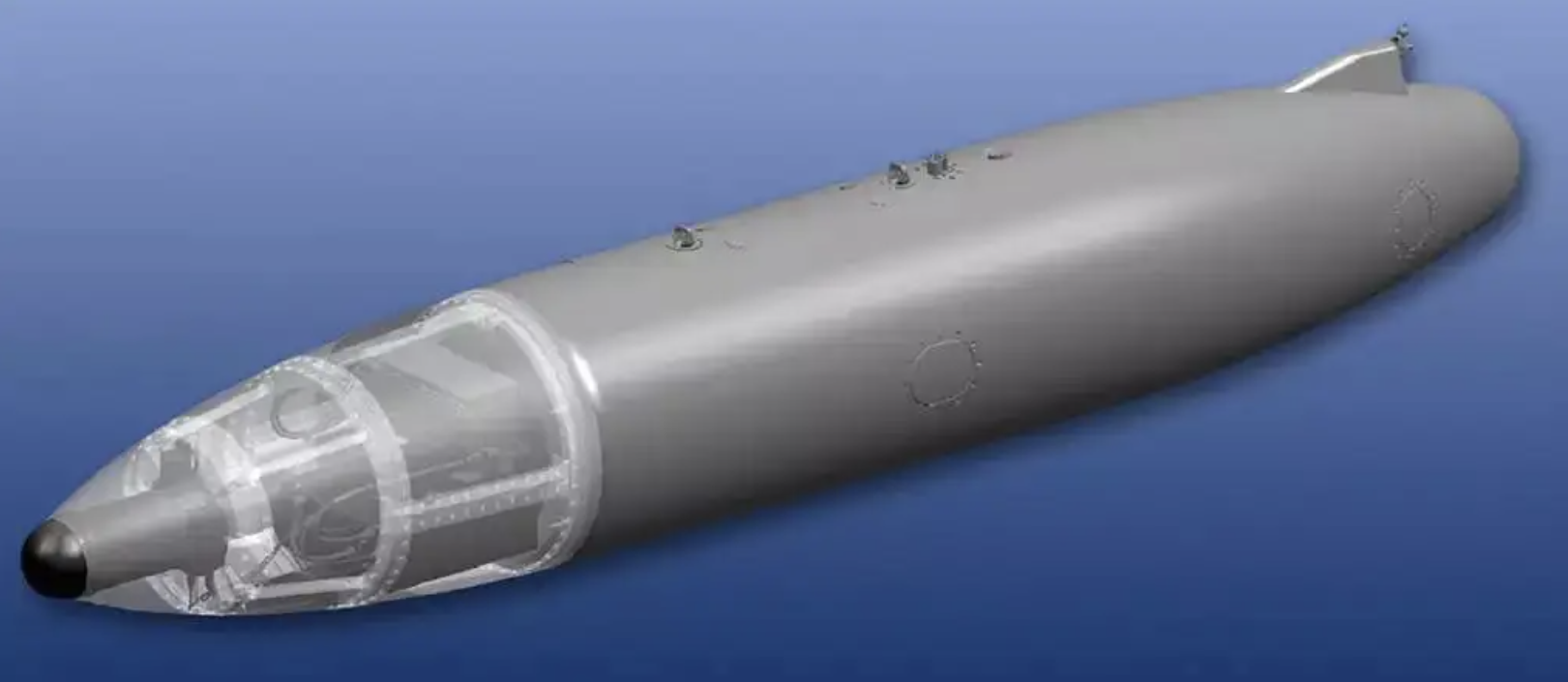

The Super Hornet’s IRST — which is installed in the nose of an external fuel tank — is clearly a big deal and an item that is only becoming more essential as potential foes like China and Russia expand their stealth and electronic warfare capabilities.

Some iteration of the pod has also been deployed on operations, carried by Super Hornets in the Middle East, with photos emerging of this in late 2020. The results of these combat trials remain unknown, and it’s not clear to what degree the pods used were actually functional, but it was a significant step to test them in this way, regardless.

So why, exactly, is the Navy having to wait so long for its IRST pod?

According to officials, “between 20 and 30 percent of the manufactured components [in the IRST pod] failed to meet performance specifications due to microelectronics issues.” More worrying still is the fact that these issues are persisting more than four years after limited manufacturing started and they are continuing to push back the launch of developmental and operational testing, as well as full-rate production.

It appears that the components affected were fiber-optic gyroscopes, considered “critical to delivering IRST capability.” To address the problem, the Navy is now meeting with manufacturer Lockheed Martin on a biweekly basis, “in an effort to improve manufacturing efficiency to support the planned rate of production.”

In more positive news, however, the same report does note that the program has “matured its one critical technology and has a stable design.”

But that won’t be much comfort for the Navy tactical aviation community who clearly want to get their hands on what is a potentially game-changing air combat tool.

Exactly when production IRST pods might start to reach the fleet is also unclear at this point. In January this year, the Navy received its first Block II production representative articles — known as infrared optimized configuration (IROC) pods. That was a full 10 months later than had been anticipated as of last year.

Once the IROC pods became available, the Navy was able to begin developmental testing, to verify that the system’s design meets all technical specifications and that all contract requirements have been met. Developmental testing is the precursor to operational testing, in which the IRST pod will be evaluated in an operational environment, and procedures and tactics developed for its use.

Completion of developmental testing is reliant upon sufficient pods being delivered, but officials are confident this will be achieved, to enable the start of operational testing in two locations in April 2024. That major milestone, if met, will be 44 months later than planned under the previous schedule.

The delays related to the launch of full-rate production also make for sobering reading. Due to the production quality issues and delays in operational testing, the full-rate production decision has been pushed back by 33 months.

To mitigate that, and keep the production line running to some degree, a seventh low-rate initial production (LRIP) lot has been added, and it may also be followed by an eighth. In the process, the number of pods acquired under the LRIP could leap to 73 — around 43 percent of the total quantity planned. However, until production quality issues are ironed out, there’s little option other than to extend the LRIP phase. The production line needs to be kept active, but at the same time, it’s too risky to move straight into full-rate production if more design changes are needed.

Other factors that have led to holdups in the program include “staffing challenges” at a critical software development contractor, and delays in the delivery of hardware, which has had a knock-on effect on software development. This meant that, by August 2022, less than half of the total software development effort had been completed. In October last year, six new software releases arrived, but, as the report warns, “significant development and testing of functionality, maintenance, and security features remains to be completed.”

However, with the delivery of the first IROC pods, the hardware issue is now considered resolved, at least until the operational testing phase.

Last year, delays with the IRST pod were already bad enough that the program was deemed to have breached its baseline schedule and a risk assessment was launched to help get it back on track.

The risk assessment led to the Navy approving a revised schedule in May 2022, which included delaying the start of operational testing by 36 months to August 2023. Of course, that has now slipped further still, until April 2024. Program officials have said there could be more delays on top of that, as well, depending on progress with software development and flight testing.

All these delays not only mean that the IRST’s long-awaited capabilities are yet to be fielded by the Navy but also push up program costs.

According to the GAO, the estimated procurement costs have risen by about 12 percent, with inflation and global supply chain disruptions also having an effect here.

Furthermore, the delays mean that the planned service life of the IRST pods has also taken a dramatic hit. Not only will they arrive far later than planned, but they will become surplus to requirements more quickly, once the Super Hornet’s successor has begun to be fielded, planned for the 2030s. The anticipated net result is a 44 percent decrease in the planned service life of the pods. While a reduced service life would also bring down operation and support costs, the saving is expected to be only 33 percent, since upfront costs for support equipment, training aids, and initial spare parts will still need to be covered.

The program office responsible for the IRST pod has meanwhile taken other actions to try and improve the situation. These include building in 45 days of schedule margin prior to operational testing and making more use of commercial aircraft to support testing.

Efforts have also been made to increase synergies between the Navy’s IRST pod and a similar pod ordered for the Air National Guard. In this way, the program office says it’s reduced unit cost between the fourth and seventh LRIP lots by 29 percent. It does, however, beg the question as to why this path wasn’t taken to start with.

Speaking to The War Zone back in 2020, Capt. Jason Denney, head of the Super Hornet and Growler program for the U.S. Navy, explained some of the differences between the Lockheed Marin IRST set-up used by the Navy and that for the Air Force:

“We haven’t done anything specifically, co-development-wise with the Air Force. There are certain [common] aspects of the IRST, what they’re developing and ours. So, with the hardware modifications, things like that, we’ve kept a lot of those common, and commonality helps us when it comes down to configuration management or being able to buy huge blocks of them. If we all had, say, the same circuit card, for example, then, hey, we combine the Air Force and the Navy buys and then we all get a better price for it. But other than that, we really haven’t done a whole lot of close coordination because their requirements and their implementation are very different than ours.”

Meanwhile, we are not aware of any significant issues encountered with the Air Force versions of the Lockheed Martin IRST, although this cannot be ruled out.

All in all, the slow progress made by the Navy’s IRST pod program is clearly a concern for the service. While the Navy may already be quietly at work on a sixth-generation successor to the Super Hornet, the fact remains that the fourth-generation jet is the backbone of the carrier air wing and will continue to be so for years to come.

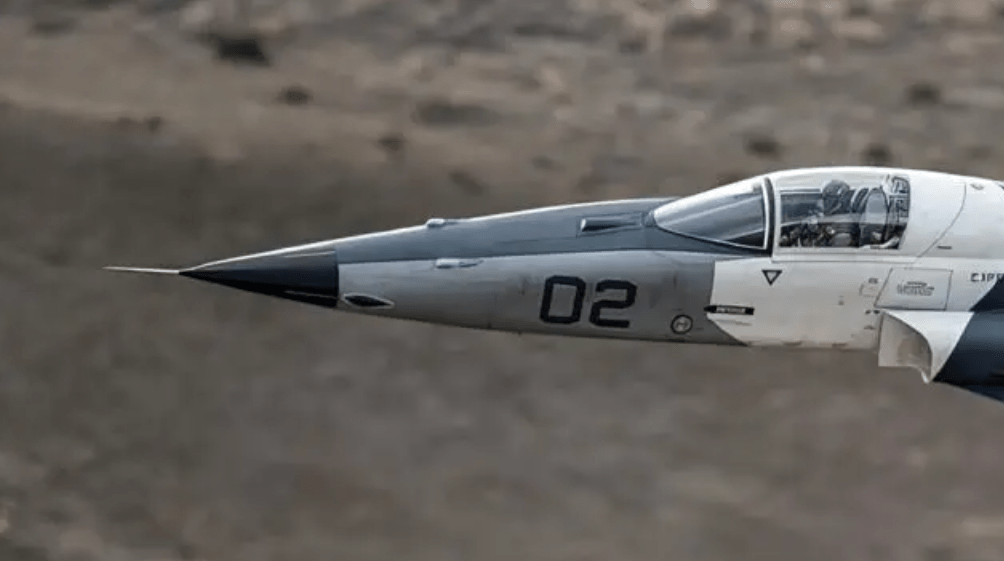

It’s also worth noting that even the contractor-operated adversary community is flying jets with IRST sensors, with Tactical Air Support announcing that it had completed initial flight testing of the Lockheed Martin-designed TacIRST, an integrated IRST sensor, on its F-5 Advanced Tiger aggressor jets late last year. While there is a capability gap between the staring-type, fixed-senor TacIRST, and the full-spec Navy system, if Lockheed Martin is able to work with Tactical Air Support to bring this capability to the threat-replication community, it begs the question of why things have been so much more difficult with the Navy.

Many potential real-world adversaries of the United States are already regularly flying with internal IRST systems, including most Russian-made high-end fighter jets, such as the Su-35 and Su-30 Flanker series, also operated by China.

Delays in giving the Super Hornet a type of sensor that has already been deployed on many other fourth-generation platforms (as well as having been retrofitted on Air Force F-15Cs and F-16Cs) is a serious issue, especially as low-observable threats are only going to proliferate and electronic warfare capabilities become an even bigger concern than they are now.

Contact the author: thomas@thedrive.com